Awesome work, i like the idea of having a means to wake the wifi module as that, like you mention, its the biggest drain on the battery but near instant controls is required for sure.

One of the biggest constraints i have is the width, there is only 24mm between the inside of the frame and the edge of the louvres when they are open, this has been the biggest challenge. I also want to have the actuator on the hinged side of the panel - so the standard clip on a louvre wont work because of the bar that links the louvers together (and i think the clip may limit the amount they close and let more light in). This is why i have stuck with the n20 motors, as there torque to size ratio is so good. I have found that slowing them down does make them noticeably quieter, and the biggest difference was applying a PTFE dry lube to the shutters, this reduced the load and noise considerably. with this design there is a changing amount of leverage too, so its only the initial opening where its noisy.

Like you and probably many others there is often a whole house of these things, and the cost when using the off the shelf ones will add up quickly. hence why i want to use cheap off the shelf components and modules from china for initial build myself designs. I will use some perf board initially for some pullups and caps, perhaps in the future ill design a small board with motor driver, current sensor and the components required for the encoder and button. The wifi modules vary in price quite a bit and i haven’t found one i like yet, but since you mentioned the lora I found the Heltec Stick lite V3 that would be absolutely ideal for this, and also includes battery management. To reduce the number of wifi connections i will just use 1 master and several slaves, linking them together with i2c as the maximum run will be <1m between nodes, in this case a much cheaper micro could be used at each actuator… this way the slaves can use a significantly cheaper mirco without any battery stuff, i was thinking a d1mini in each one with wifi turned off - but having the option to turn it on via i2c for updates.

rough prices from aliexpress, not including shipping/taxes

encoder $0.20

tactile $0.05

drv8833 motor driver $1.00

i2c current sensor $1.50

n20 motor $1.50

magnets $0.10

battery terminals $0.60

Resin $3

heltec lite v3 $33

D1 mini $4

A whopping total of $40 for the master and $10 per slave… that’s what ill tell my wife anyway… i’ve probably burned through a bottle of resin already prototyping and spent hundreds on motors, modules and components that will probably sit in a draw. not mentioning the number of hours designing

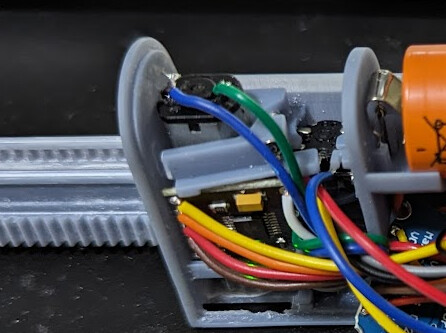

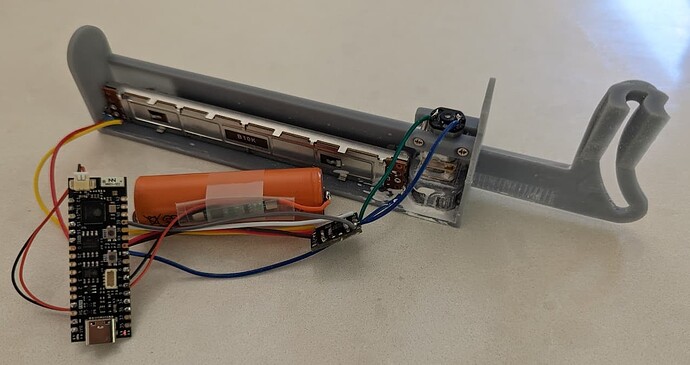

I’ve been working on another new version that should allow for significantly more room for electronics, and will also include an 18650 holder. I’ve also put loads of effort into making it quick to assemble. I’ve removed many of the limit switches, just the one that is on the rack the motor drives, the rack is magnetically coupled to the actuator arm. there is a mouse wheel encoder on the actuator arm to detect position and any manual movement and weather the magnet is linked or not. Because i want to make this thing easy to assemble and solder the tactile switch and encoder just clip in in a way where the wires can be pre-soldered or even easily soldered once installed, the motor driver will just sit in a groove and the motor clamp will hold it in place with just a single 2x8mm screw. this is still a work in progress… i haven’t even got to the teeth on the rack yet. The body is 22mm x 44mm x 110mm. and the actuator arm is 230mm long overall

I found resin on resin is just too much drag and with clearances big enough to reduce drag it gets sloppy, it also requires significant lubrication which will probably require regular maintenance. A notable change in this design is to use 1mm dowel pins as linear bearings, i will play with the size and see how reliable it is. With the transparency turned up you can see the recess where a 16mm long dowel sits captured, it then sits in the grove of the moving parts holding it in place. I have ordered a small kit with m1 and m1.5 pins of various lengths, the 1mm gives 0.5mm to the outside edge, if i change to 1.5mm it gets pretty thin at 0.25mm. buying the precut and ground pins will probably work out to about $1.50 per unit (6pce)

I guess maybe not now.

I guess maybe not now.