ESPHomeAlpineBoiler

Documentation for ESPHome Modbus Alpine Boiler Interface. I hope it helps. I went from no experience with ESPHome or Modbus to getting this working in about 2 days. Hopefully, this will help others be quicker.

This is a short tutorial to add an Alpine Burnham (US Boiler) Boiler to homeassistant. Tested on model number: ALP150BW-4T02 but should work on most similar models.

Putting this together leveraged research from many people online, amazon comments, etc:

- mini-monitor/sage_boiler.py at 2a5aa291621a5854905e9478b27a4e6be3f260f4 · alanmitchell/mini-monitor · GitHub

- sage2-boiler/sage_boiler.py at a68b0b43a903ca77330988d63fe86876771404aa · jdleslie/sage2-boiler · GitHub

- https://www.ccontrols.com/support/dp/Sage2.doc

- Hardware — Mini-Monitor Documentation 0.0.1 documentation

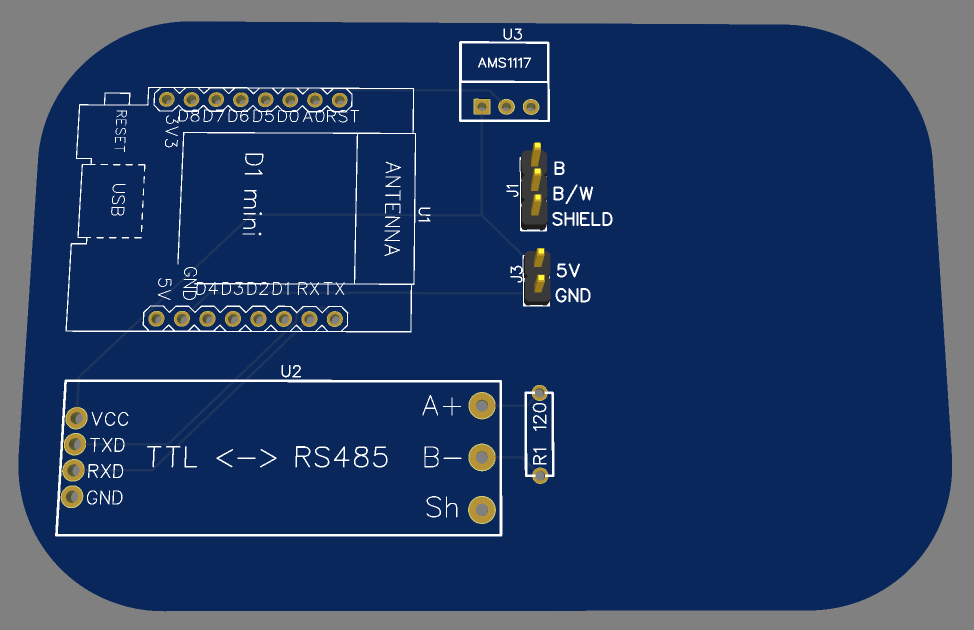

Components Needed (Just a few bucks for all of this):

- TTL to RS485 Module 485 . https://www.amazon.com/gp/product/B07YZTGHGG Could use the more common Max485, but this board is a little easier as does not need flow control.(but may need a resister). If you use the Max485, you need to set the flow control pin and do more complicated wiring.

- Wemos Mini D1. https://www.amazon.com/gp/product/B081PX9YFV . Could use any ESP module you like, but these are cheap

- Cat 5/6 Ethernet Cable (which you will destroy)

- 120 Ohm Resistor. (I used a 100 Ohm and still worked) This was the trick, without this I was beating my head against the wall!

Prep the Boiler:

You must set the “Boiler Address” to 1 in order to read data from the boiler. This is done on the “Adjust”, “Sequence Slave”, “Boiler Address” menu item available through the touch screen control on the boiler. The Factory default for this setting is “None”, so it must be changed in order for the monitoring system to work. The default password is 76 , if it asks you for one.

Install ESPHome:

Load ESPHome onto the Wemos. Do this first. Just load a standard firmware, so you can update it later without needing to program it manually. Make sure you also have the ESPHome integration loaded. Below wiring instructions assume you power the Wemos D1 via USB so the 5V pin is energized.

Solder the Components:

You need to solder the Wemos to the RS485 Adapter and the RS485 Adapter to the CAT 5/6 Cable and resister.

First for the Wemos to RS485:

| Wemos | RS485 | Comment |

|---|---|---|

| 5V | Vcc | Works best with 5 V |

| RX | RX | Yes, RX to RX. Not a mistake. This 485 board is labeled this way! |

| TX | TX | Yes, TX to TX. Not a mistake.This 485 board is labeled this way! |

| G | G |

I have confirmed my boards are wired TX-TX and RX-RX. Another user says theirs needed to be TX-RX and RX-TX, so try both if yours is not working. Be sure to power the Wemos D1 via USB so the 5V pin is energized.

Next for the RS485 to the Cat 5/6 Cable

| RS485 | Cat 5/6 | Comment |

|---|---|---|

| A+ | Pin 8 | Often this is the brown cable. Will be twisted with brown/white cable |

| B- | Pin 7 | Often this is the brown/white cable. Will be twisted with brown cable |

| G Labeled with a Chinese Character | Pin 6 | Often this is green. Might be optional, but I did it |

Now the big trick is if your cable is short (mine was) you need a 120 Ohm resistor between A+ and B- wires near the adapter. I soldered it across the two (Brown and Brown/White) CAT5 wires, a few mm before the 485 Module. Without this, you will get reflections and get error messages in ESPHome and nothing worked. Once I did this, things worked perfectly.

Now connect other side of CAT 5/6 cable to the boiler. The boiler controller has a MODBUS RS485 interface that is accessed through a standard RJ45 jack on the side of the boiler. You want the top jack labeled “Boiler to Boiler”.

Now, you can go back into ESPHome and load the following YAML onto the WEMOS. These are the sensor’s I am using. If you want more sensors, you can look at the code linked at the top of the page, to add more holding register sensors. I will update this code as I learn more. But this should give you the most important sensors. There are two ways to determine the firing rate. I used the method that worked for mine. I also scale the firing rate to Btu/h to match what is displayed on the boiler display panel.

esphome:

name: boiler

esp8266:

board: d1_mini

uart:

id: mod_bus

tx_pin: GPIO1

rx_pin: GPIO3

baud_rate: 38400

modbus:

id: modbus1

modbus_controller:

- id: vlb

## the Modbus device addr

address: 0x1

modbus_id: modbus1

setup_priority: -10

command_throttle: 100ms

sensor:

- platform: modbus_controller

modbus_controller_id: vlb

name: "outlet_temp"

id: outlet_temp

register_type: holding

address: 0x7

value_type: U_WORD

accuracy_decimals: 1

filters:

- lambda: return x * 0.18 + 32.0;

unit_of_measurement: "°F"

- platform: modbus_controller

modbus_controller_id: vlb

name: "fan_rate"

id: fan_rate

register_type: holding

address: 0x8

value_type: U_WORD

accuracy_decimals: 1

bitmask: 0x7FFF

unit_of_measurement: "rpm"

- platform: modbus_controller

modbus_controller_id: vlb

name: "max_rpm"

id: max_rpm

register_type: holding

address: 193

value_type: U_WORD

accuracy_decimals: 1

unit_of_measurement: "rpm"

- platform: template

name: "firing_rate"

lambda: |-

return 118000.0 * id(fan_rate).state / id(max_rpm).state;

unit_of_measurement: "Btu/h"

- platform: modbus_controller

modbus_controller_id: vlb

name: "outdoor_temp"

id: outdoor_temp

register_type: holding

address: 170

value_type: U_WORD

accuracy_decimals: 1

unit_of_measurement: "°F"

filters:

- lambda: |-

if (x > 32767 ) {

return (x - 65536.0) * 0.18 + 32.0;

} else {

return x * 0.18 + 32.0;

}

# Alpine 150 = BTU Heat Rating: 118000 Btu/h

binary_sensor:

- platform: modbus_controller

modbus_controller_id: vlb

id: ch_demand

name: "Heat Demand"

register_type: holding

address: 66

- platform: modbus_controller

modbus_controller_id: vlb

id: water_demand

name: "Water Demand"

register_type: holding

address: 83

# Enable logging

logger:

level: VERBOSE

baud_rate: 0

# Enable Home Assistant API

api:

ota:

password: "UseAGoodPassword"

wifi:

ssid: !secret wifi_ssid

password: !secret wifi_password

# Enable fallback hotspot (captive portal) in case wifi connection fails

ap:

ssid: "Boiler Fallback Hotspot"

password: "UseAGoodPassword"

captive_portal:

web_server:

port: 80

the ALP150 is rated at 118000.0 BTU. If you have a different model, update the value in the YAML to match your maximum output.