Thank you guys for sharing the above, took some inspiration and made a variant with multiple inverters.

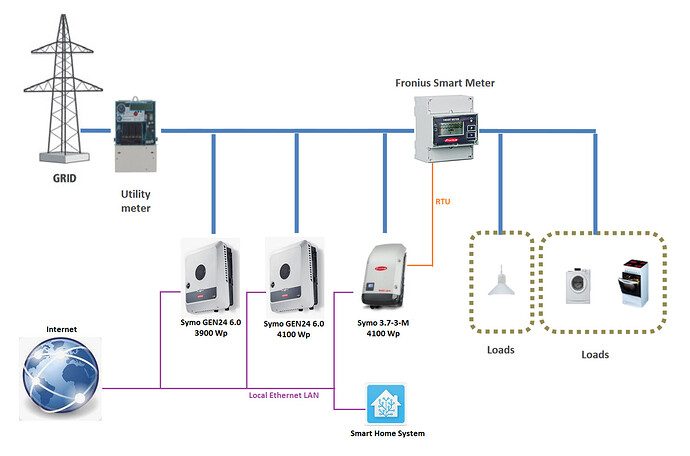

This is like a Plant Controller where multiple inverters (different in size) need to be adjusted in parallel based on information coming from a single Fronius SmartMeter. Actually I think any kind of “smart” meter could be used with this approach, as it doesn’t interact directly with any of the inverters, only through HA automation.

See attached picture. The SmartMeter (in consumption path) is attached to one of the inverters with DataManager card, but there’s two new GEN24 inverters added to the system, which don’t connect to the SmartMeter.

I have no automated limiting options enabled in any of the inverters. I only define the priorty so that “Controlling via Modbus” will be first, and of course enable “Inverter control via Modbus”. SunSpec model tpye is “Int + SF”.

With these settings to limit manually the output power, one has to change the percentage output at holding register 40233, and then enables throttling by writing value 1 to register number 40237 (In Fronius’s docs the addresses are base1, but since HA uses base0, we use address numbers decreased by 1, that’s why also in the examples above we have addresses 40232 and 40236 accordingly).

As a cleaner approach, I decided to read the data from the inverters with the same modbus integration as is used to write the registers. This is independent from the Fronius or SunSpec integrations.

modbus:

- name: inverter_symo #repeat this section for other two gen24 inverters

type: tcp

host: 192.168.1.80

port: 502

retry_on_empty: true

retries: 3

delay: 3

sensors:

- name: smartmeter_w_raw #adding this only to the inverter where the SmartMeter connects

slave: 240 #(snapinverter symo: 240, gen24 default: 200)

input_type: holding

address: 40087

scan_interval: 5

unique_id: smartmeter_w_raw

count: 5

data_type: custom

structure: ">hhhhh"

- name: inverter_symo_raw_lim

slave: 1

input_type: holding

address: 40232

scan_interval: 5

unique_id: inverter_symo_raw_lim

count: 5

data_type: custom

structure: ">hhhhh"

- name: inverter_symo_raw_w

slave: 1

input_type: holding

address: 40083

scan_interval: 5

unique_id: inverter_symo_raw_w

count: 2

data_type: custom

structure: ">hh"

Template sensors to calculate from modbus raw registers and scaling factors:

sensor:

- name: "Smartmeter W"

unique_id: smartmeter_W

state_class: measurement

device_class: power

unit_of_measurement: W

icon: mdi:home-lightning-bolt

availability: "{{ has_value('sensor.smartmeter_w_raw') }}"

state: >

{{

(states('sensor.smartmeter_w_raw').split(',')[0]) | int(default=0)

/10**(states('sensor.smartmeter_w_raw').split(',')[4] | int(default=0)*-1)

}}

- name: "Inverter Symo W"

unique_id: inverter_symo_W

state_class: measurement

device_class: power

unit_of_measurement: W

icon: mdi:solar-power

availability: "{{ has_value('sensor.inverter_symo_raw_w') }}"

state: >

{{

(states('sensor.inverter_symo_raw_w').split(',')[0]) | int(default=0)

/10**(states('sensor.inverter_symo_raw_w').split(',')[1] | int(default=0)*-1)

}}

- name: "Inverter Symo limiter percentage"

unique_id: inverter_symo_WMaxLimPct

state_class: measurement

unit_of_measurement: "%"

icon: mdi:car-cruise-control

availability: "{{ has_value('sensor.inverter_symo_raw_lim') }}"

state: >

{{ (states('sensor.inverter_symo_raw_lim').split(',')[0] | int(default=10000))/100 }}

binary_sensor:

- name: "Inverter Symo limiter enabled"

unique_id: inverter_symo_limiter

icon: mdi:car-speed-limiter

availability: "{{ has_value('sensor.inverter_symo_raw_lim') }}"

state: >

{{ (states('sensor.inverter_symo_raw_lim').split(',')[4] | bool(default=false)) }}

The above is for the Symo, similar config is added for the other two inverters (without the SmartMeter sensor of course).

What I did so far is I decided to also have an input_number to configure the maximum export value. Note that this can also be negative, for some very strict conditions when you want to make 100% sure that absolutely no power is fed into the grid, but some little is always drawn:

input_number:

- max_export:

name: Maximum export

min: -300

max: 10000

step: 100

icon: mdi:transmission-tower-import

unit_of_measurement: 'W'

The approach here is that you can use a separate automation to simply adjust this number when you don’t want to feed in, or you want to feed just until a maximum value.

Calculation of the target percentage happens similarly as in the examples above. My smartmeter is in the consumption path.

Needed to define two sensors because the Symo is 3700W, the other two GEN24s are 6000W (they can use the same template sensor).

Note that since there are 3 inverters, we divide the sum by 3, so we distribute the limits accordingly to the inverters.

- name: "Inverter Symo limit"

unique_id: inverter_target_limit_sym

state_class: measurement

state: >

{% set proc = ((states("sensor.smartmeter_w")|float(default=0)-states("input_number.max_export")|float(default=0))/3/3700)|multiply(-1)|multiply(10000)|int %}

{% if proc > 10000 %}10000{% elif proc < 0 %}0{% else %}{{ proc }}{% endif -%}

- name: "Inverter Gen24 limit"

unique_id: inverter_target_limit_gen

state_class: measurement

state: >

{% set proc = ((states("sensor.smartmeter_w")|float(default=0)-states("input_number.max_export")|float(default=0))/3/6000)|multiply(-1)|multiply(10000)|int %}

{% if proc > 10000 %}10000{% elif proc < 0 %}0{% else %}{{ proc }}{% endif -%}

And the automations:

- alias: Inverter limiter Symo

mode: single

trigger:

- platform: state

entity_id:

- sensor.inverter_symo_limit

action:

- choose:

- conditions: # this is for the case when export limit is to be disabled

- condition: template

value_template: "{{ states('sensor.inverter_symo_limit')|int == 10000}}"

sequence:

- service: modbus.write_register

data:

unit: 1

hub: inverter_symo

address: 40232

value: "10000"

- service: modbus.write_register

data:

unit: 1

hub: inverter_symo

address: 40236

value: "0"

default:

- service: modbus.write_register

data:

unit: 1

hub: inverter_symo

address: 40232

value: "{{ states.sensor.inverter_symo_limit.state }}"

- service: modbus.write_register

data:

unit: 1

hub: inverter_symo

address: 40236

value: "1"

- alias: Inverter limiter Gen24

mode: single

trigger:

- platform: state

entity_id:

- sensor.inverter_gen24_limit

action:

- choose:

- conditions:

- condition: template

value_template: "{{ states('sensor.inverter_gen24_limit')|int == 10000}}"

sequence:

- service: modbus.write_register

data:

unit: 1

hub: inverter_gen24_a

address: 40232

value: "10000"

- service: modbus.write_register

data:

unit: 1

hub: inverter_gen24_b

address: 40232

value: "10000"

- service: modbus.write_register

data:

unit: 1

hub: inverter_gen24_a

address: 40236

value: "0"

- service: modbus.write_register

data:

unit: 1

hub: inverter_gen24_b

address: 40236

value: "0"

default:

- service: modbus.write_register

data:

unit: 1

hub: inverter_gen24_a

address: 40232

value: "{{ states.sensor.inverter_gen24_limit.state }}"

- service: modbus.write_register

data:

unit: 1

hub: inverter_gen24_b

address: 40232

value: "{{ states.sensor.inverter_gen24_limit.state }}"

- service: modbus.write_register

data:

unit: 1

hub: inverter_gen24_a

address: 40236

value: "1"

- service: modbus.write_register

data:

unit: 1

hub: inverter_gen24_b

address: 40236

value: "1"

Result (with max_export set to 1700):

The production of the 3 inverters dynamically follows the house demand, always feeding in not more than 1700W.