Introduction:

I will be refurbishing an old house. The electrical installation will be completely redone. This is the opportunity to create the automation I want and integrate it with Home Assistant.

I have a lot of ESPHome devices in my current house (heater, ventilation, rain water, community water, water softener, security alarm, lights, …), and many other integrations (Solar, EVSE, cars, …). Integrating the lights in an existing installation with HA in a way that is transparent to the user, works when HA is down and is easy the reverse when moving out is the most tedious.

For the new place I will run all the lights with Siemens LOGO! PLCs and interface those PLCs with HA. That is what this thread is about.

It is important that everything will work when HA is down. The only difference the user will immediately experience is the use of push buttons to toggle the lights rather than conventional on/off switches.

The basic setup:

I will have a PLC on the main distribution board and on each of a few (TBD) secondary distribution boards. All light points will be wired directly to the distribution boards (for connection to the PLC relays). All push buttons will have low voltage wiring to the distribution boards (for connection to the PLC digital inputs).

I have chosen to use the Modbus not the MQTT integration to interface the LOGO! PLCs with HA.

Getting connected:

I have an old “LOGO! Soft Comfort” (version 6.?) software on a CD. I was able to upgrade that to version 8.4 for use with the new networked LOGO! PLCs. And I purchased a LOGO!12/24RCE (6ED1052-1MD08-0BA2) to get started.

I found a video explaining how to connect the LOGO! to the PC.

Note:

This was the first time ever I had to set up an IP address, the mask and the gateway for a LAN connection. That threw me off for a second, but with this video it was straight forward.

And a video explaining the basic LOGO! block diagram and HA yaml code needed:

Note:

In this video I got stuck around the 3:20 mark. The data table in the video immediately shows up populated, but the first time you have to do that yourself by adding the network interfaces (V0.0, …) in the first column! My search found others getting stuck here, but no answers. Here it is, you are welcome.

This got me connected. And now I am trying different options for how the LOGO! and HA are going to work together.

LOGO! and HA

Each PLC output (light) will be defined with a pulse relay. The pulse relays can be toggled from a PLC input (button) to switch the lights.

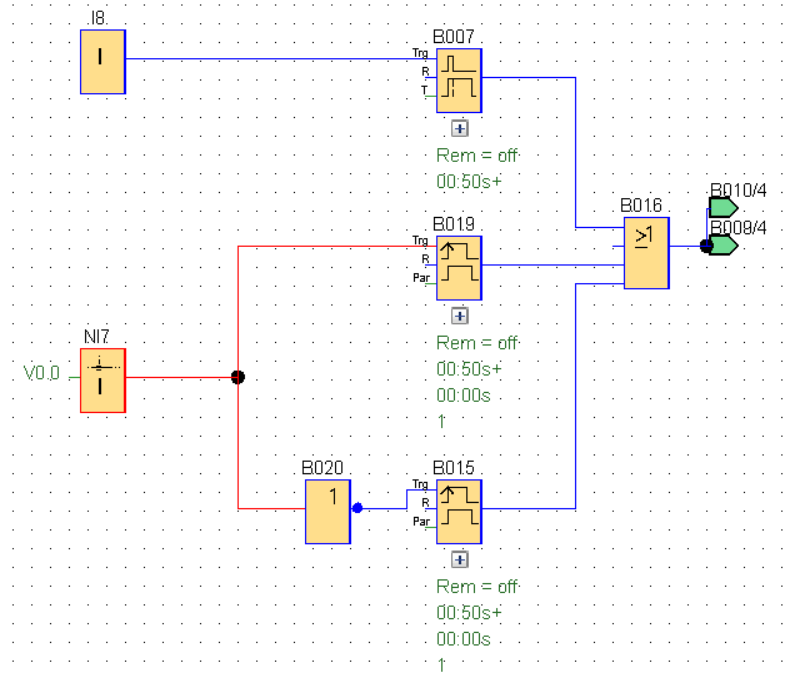

From HA I want to be able to toggle, set or reset the pulse relays. Each of these actions require a pulse (on the T, S or R input of the pulse relay). So I created an input (with debounce) to connect to a button and three network inputs to toggle, set or reset the relay:

The network inputs will be connected to a switch in HA. There is a switch action to ‘switch on’, ‘switch off’ or to ‘toggle’ a switch in HA, but none to generate a pulse (maybe there should be?). So I explored simply toggling the switch and have the PLC generate the pulses like this:

But then decided that creating the pulse in HA seemed less of a work-around. So I created a script for each switch to generate a pulse.

#

# *** SIEMENS LOGO! PACKAGE ***

#

# Modbus definition

modbus:

- name: "LOGO"

type: tcp

host: 192.168.178.200

port: 502

delay: 5

timeout: 2

# SWITCHES

switches:

- name: Switch_10

address: 8 # V1.0

write_type: coil

command_on: 1

command_off: 0

- name: Switch_11

address: 9 # V1.1

write_type: coil

command_on: 1

command_off: 0

- name: Switch_12

address: 10 # V1.2

write_type: coil

command_on: 1

command_off: 0

# BINARY SENSORS

binary_sensors:

# Output Q1

- name: Q1

address: 8192

input_type: coil

scan_interval: 1

unique_id: E8A2B3B0D5

# SCRIPTS

script:

# Create pulse outputs for the LOGO! network inputs

pulse_v10:

alias: Pulse V1.0

sequence:

- action: switch.turn_off

target:

entity_id:

- switch.switch_10

- action: switch.turn_on

target:

entity_id:

- switch.switch_10

- delay:

hours: 0

minutes: 0

seconds: 0

milliseconds: 500

- action: switch.turn_off

target:

entity_id:

- switch.switch_10

pulse_v11:

alias: Pulse V1.1

sequence:

- action: switch.turn_off

target:

entity_id:

- switch.switch_11

- action: switch.turn_on

target:

entity_id:

- switch.switch_11

- delay:

hours: 0

minutes: 0

seconds: 0

milliseconds: 500

- action: switch.turn_off

target:

entity_id:

- switch.switch_11

pulse_v12:

alias: Pulse V1.2

sequence:

- action: switch.turn_off

target:

entity_id:

- switch.switch_12

- action: switch.turn_on

target:

entity_id:

- switch.switch_12

- delay:

hours: 0

minutes: 0

seconds: 0

milliseconds: 500

- action: switch.turn_off

target:

entity_id:

- switch.switch_12

# END