The Smarter.am cloud service is (for all intents and purposes) dead. AFAIK, all Smarter products are therefore no longer ‘smart’. Long live ESPHome!

With help from the information in this guide, I’ve successfully converted my Smarter iKettle 3.0 to ESP32/ESPHome. My project is a bit more ambitious. I’ve completely replaced the logic board within the iKettle 3.0, and have attempted to replicate all of its functions (with one exception), including:

- No change to appearance/no additional wires

- Retain original power button and power LED

- RGB LED to show WiFi connection status

- HX711 to read the load cell to weigh the kettle to estimate fill level

- Buzzer to indicate turn on/off or on error

- Connect to and read kettle thermistor for auto-off/thermostatic control

I haven’t bothered trying to replicate the light sensor/LDR that interprets flashes from your phone’s screen to upload WiFi connection details for initial setup.

DISCLAIMER: Probably don’t do this. I’m no expert. I’m scraping by with an electronics GCSE from 1999, ChatGPT, a multimeter, basic soldering iron and awareness of the potential dangers. That said, such a disclaimer wouldn’t have stopped me, so I’m sharing my work for likeminded people.

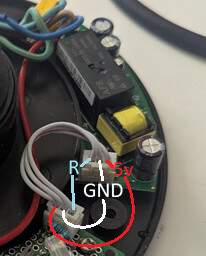

Opening up the iKettle base, you’ll find a 3-wire connector joining the power board and the logic board. These three wires are a 5v supply, GND and connection to the positive side of the relay coil. Bridging the 5v and relay control wires causes the relay to click on and would provide power to the kettle element.

So, safety aside, this is a pretty easy conversion. We can leave the power board alone, and build something that can read the kettle temp and connect 5v to the relay control wire to turn on/disconnect to turn off.

Parts list:

- ESP32-S3 Mini

- HX711 ADC/pressure sensor to measure weight

- RGB LED (common cathode) for status indication

- White LED for power indication

- Active buzzer for the beep

- PN2222 transistor

- 104pF ceramic cap

- 3 x 330 ohm resistors

- 1 x 47k resistor for the thermistor (10k might be better - not sure)

- Right angle push button

- JST-XH connector kit

- Assorted multicoloured wire

Tools:

- Soldering iron

- Philips screwdriver

- Wire strippers

- Multimeter (to check continuity across joined connections/voltages)

- 2.54mm crimp tool

- Dremel to cut perf board

- Thermometer (to read water temp and tune the thermistor values accordingly)

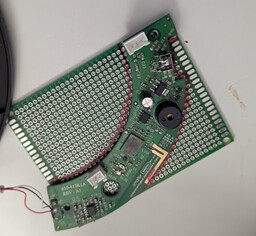

I started by attempting to cut a perf board to roughly the same shape as the original iKettle logic board:

I then attempted to situate the components in the only way I could get them all to fit. I had to sacrifice one of the screw holes by the status LED, and had to cut the standoff to make room for my new board.

I’ve neglected to take a photo of the underside of my board, but honestly that wouldn’t necessarily help because it’s a bit of a mess.

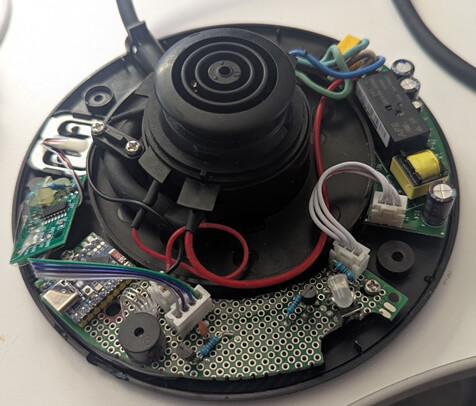

Here’s what my board looks like installed. I soldered JST-XH connectors onto the board for the connection to the power board, HX711 and thermistor so that it can be removed easily. The load cell and resistors required to create a ‘half bridge’ (see diagram) are soldered to the HX711 itself:

The HX711 is just kinda placed inside, unsecured.

Ignore the second transistor next to the buzzer. It’s not needed.

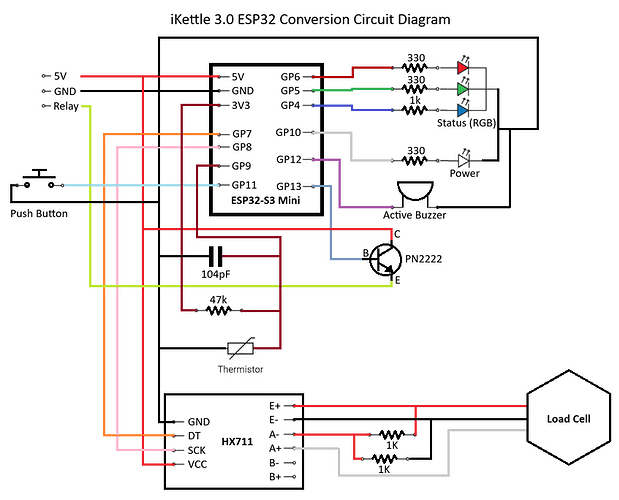

Here’s my circuit diagram:

Note that the thermistor is not on the board, it’s inside the kettle itself. On the board I have a 2-pin HX-2A connector, which re-uses the existing connector. The same applies to the 5v/GND/Relay connections - I’ve soldered an HX-3A to the board and am re-using the existing connector.

…and here’s my YAML:

esphome:

name: smart_kettle

friendly_name: "Smart Kettle"

on_boot:

priority: -100

then:

- script.execute: boot_led_sequence

esp32:

board: esp32-s3-devkitc-1

framework:

type: arduino

logger:

level: info

api:

encryption:

key: !secret api_key

ota:

- platform: esphome

password: !secret ota_password

wifi:

ssid: !secret wifi_ssid

password: !secret wifi_password

on_connect:

then:

- script.execute: wifi_connected

captive_portal:

web_server:

port: 80

status_led:

pin: GPIO48

globals:

- id: kettle_on

type: bool

restore_value: no

initial_value: "false"

switch:

- platform: gpio

id: rgb_red

pin: GPIO6

internal: true

- platform: gpio

id: rgb_green

pin: GPIO5

internal: true

- platform: gpio

id: rgb_blue

pin: GPIO4

internal: true

- platform: gpio

id: power_led

pin: GPIO10

internal: true

- platform: gpio

id: buzzer

pin: GPIO12

internal: true

- platform: gpio

id: relay

pin: GPIO13

restore_mode: ALWAYS_OFF

internal: true

on_turn_on:

- globals.set:

id: kettle_on

value: "true"

- script.execute: relay_safety_timer

on_turn_off:

- globals.set:

id: kettle_on

value: "false"

- switch.turn_off: power_led

- platform: template

name: "Smart Kettle"

icon: mdi:kettle

lambda: |-

return id(kettle_on);

turn_on_action:

- script.execute: kettle_on_request

turn_off_action:

- script.execute: kettle_off_sequence

binary_sensor:

- platform: gpio

id: power_button

pin:

number: GPIO11

mode: INPUT_PULLUP

inverted: true

on_press:

- script.execute: kettle_toggle_request

- platform: template

id: kettle_on_base

name: "Kettle On Base"

lambda: |-

return id(load_cell).state < -80000;

on_release:

then:

- if:

condition:

lambda: 'return id(kettle_on);'

then:

- script.execute: kettle_off_sequence

sensor:

- platform: hx711

id: load_cell

name: "Load Cell"

dout_pin: GPIO7

clk_pin: GPIO8

update_interval: 200ms

filters:

- median:

window_size: 7

send_every: 3

unit_of_measurement: "g"

accuracy_decimals: 0

internal: true

- platform: template

name: "Kettle Fill Percentage"

lambda: |-

float w = id(load_cell).state;

float pct = (w + 119000.0) / (-445000.0 + 119000.0) * 100.0;

if (pct < 0) pct = 0;

if (pct > 100) pct = 100;

return pct;

unit_of_measurement: "%"

update_interval: 2s

- platform: adc

pin: GPIO9

id: adc_ntc

attenuation: 11db

update_interval: 2s

- platform: resistance

id: ntc_res

sensor: adc_ntc

resistor: 47kOhm

configuration: DOWNSTREAM

- platform: ntc

id: kettle_temp_raw

sensor: ntc_res

calibration:

b_constant: 3931

reference_resistance: 50.9kOhm

reference_temperature: 25

- platform: template

id: kettle_temp

name: "Kettle Temperature"

lambda: |-

return (id(kettle_temp_raw).state + 16.7) * (85.8 / 67.7) + 14.2;

unit_of_measurement: "°C"

accuracy_decimals: 1

update_interval: 2s

filters:

- lambda: |-

if (x < 0 || x > 120) return NAN;

return x;

- sliding_window_moving_average:

window_size: 5

send_every: 1

on_value:

then:

- if:

condition:

lambda: 'return x >= 100.0 && id(kettle_on);'

then:

- script.execute: kettle_off_sequence

script:

- id: kettle_toggle_request

then:

- if:

condition:

lambda: 'return id(kettle_on);'

then:

- script.execute: kettle_off_sequence

else:

- script.execute: kettle_on_request

- id: kettle_on_request

then:

- if:

condition:

and:

- binary_sensor.is_on: kettle_on_base

- lambda: 'return id(kettle_temp).state < 100.0;'

then:

- switch.turn_on: relay

- switch.turn_on: power_led

- switch.turn_on: buzzer

- delay: 200ms

- switch.turn_off: buzzer

else:

- script.execute: error_beep

- id: relay_safety_timer

mode: restart

then:

- delay: 120s

- if:

condition:

lambda: 'return id(kettle_on);'

then:

- script.execute: kettle_off_sequence

- id: kettle_off_sequence

then:

- switch.turn_off: relay

- switch.turn_off: power_led

- repeat:

count: 3

then:

- switch.turn_on: buzzer

- delay: 250ms

- switch.turn_off: buzzer

- delay: 250ms

- id: error_beep

then:

- repeat:

count: 5

then:

- switch.turn_on: buzzer

- delay: 250ms

- switch.turn_off: buzzer

- delay: 250ms

- id: boot_led_sequence

mode: restart

then:

- while:

condition:

not:

wifi.connected:

then:

- switch.turn_on: rgb_blue

- delay: 250ms

- switch.turn_off: rgb_blue

- delay: 250ms

- id: wifi_connected

then:

- switch.turn_off: rgb_blue

- switch.turn_on: rgb_green

For testing, you’ll want to set comment out the ‘internal: true’ lines so that all the controls/sensor values will be displayed on the web portal for testing/tuning, and then you can update the YAML accordingly. To tune the load cell and thermistor readings, paste the YAML into ChatGPT and say ‘help me to correct these sensor values’, and provide the readings when the kettle is on/off the base, empty versus full, room temp water versus boiling, etc.), it’ll do the work for you.

There are no doubt many improvements that could be made to the code. Feel free to let me know.

I spent a good few days on this, all so I can once again control my kettle via HA/Alexa. Was it worth it? Of course!