Hi all,

After reading a few post on here about flow measurements, I’ve bought a TUF-2000M with the small TS-2 sensors. This is running just fine over modbus with esphome on an ESP32 + RS485 converter. My config is as follows in case you’re also trying to do this:

uart:

id: mod_bus_uart

tx_pin: GPIO17

rx_pin: GPIO16

baud_rate: 9600

# debug:

# direction: BOTH

modbus:

id: modbus1

uart_id: mod_bus_uart

send_wait_time: 500ms

modbus_controller:

- id: tuf2000m

address: 0x1

modbus_id: modbus1

setup_priority: -10

update_interval: 3s # TODO: Default is 60, makes more sense once in prod

sensor:

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow rate"

register_type: holding

address: 0x1 # Register 1

register_count: 2

value_type: FP32

device_class: "volume_flow_rate"

state_class: "measurement"

unit_of_measurement: "g/m"

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Velocity"

register_type: holding

address: 0x3 # Register 3

register_count: 2

value_type: FP32

device_class: "speed"

state_class: "measurement"

unit_of_measurement: "m/s"

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Positive Accumulator"

register_type: holding

address: 0x9 # Register 9

register_count: 2

value_type: FP32

device_class: "water"

state_class: "measurement"

unit_of_measurement: "g"

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Temperature #1"

register_type: holding

address: 0x21 # Register 33

register_count: 2

value_type: FP32

device_class: "temperature"

state_class: "measurement"

unit_of_measurement: "°C"

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Temperature #2"

register_type: holding

address: 0x23 # Register 35

register_count: 2

value_type: FP32

device_class: "temperature"

state_class: "measurement"

unit_of_measurement: "°C"

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Signal Quality"

register_type: holding

address: 0x5C # Register 92

register_count: 1

value_type: U_WORD

lambda: |-

return (uint16_t)(x) & 0xff;

state_class: "measurement"

unit_of_measurement: "%"

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Upstream Strength"

register_type: holding

address: 0x5D # Register 93

register_count: 1

value_type: U_WORD

state_class: "measurement"

lambda: |-

return (x/2048.0)*100.0;

unit_of_measurement: "%"

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Downstream Strength"

register_type: holding

address: 0x5E # Register 94

register_count: 1

value_type: U_WORD

state_class: "measurement"

lambda: |-

return (x/2048.0)*100.0;

unit_of_measurement: "%"

binary_sensor:

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error No Signal"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x1

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Low Signal"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x2

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Poor Signal"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x4

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Pipe Empty"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x8

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Hardware Failure"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x10

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Gain Ajusting"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x20

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Freq Overflow"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x40

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error RAM CS"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x100

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Clock"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x200

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Parameters CS"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x400

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error ROM CS"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x800

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Temp Circuits"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x1000

- platform: modbus_controller

modbus_controller_id: tuf2000m

name: "${friendly_name} Flow Meter Error Internal timer"

register_type: holding

address: 0x48 # Register 72

bitmask: 0x4000

What I have problems with is getting it to actually work though. I live in the US and have new 1" copper pipe (type L). When measuring these I get an OD of 28.6mm, ID of 26.0mm and a wall thickness of 1.3mm. (A bit thicker than the standard says it should be but that’s a good thing I guess. Plugging in the standard’s numbers makes no real difference.)

When feeding these parameters into the unit I get a distance of ~4mm in V setup and 11mm in a W setup. In either configuration I can get to a signal quality of ~85 with some variance between 78 and 90 over time and fiddling. However neither of these happens at the distance the unit indicates, I’m always a few mm off (it’s actually not clear how to exactly measure but I assume just between the sensors going by the images in the manual).

However going by the manual after this step the next one is to get the TOM/TOS ratio around 100 ±3. In neither setup I’ve gotten anywhere near this. In the V config it was around 111 and in the W config it’s 76%

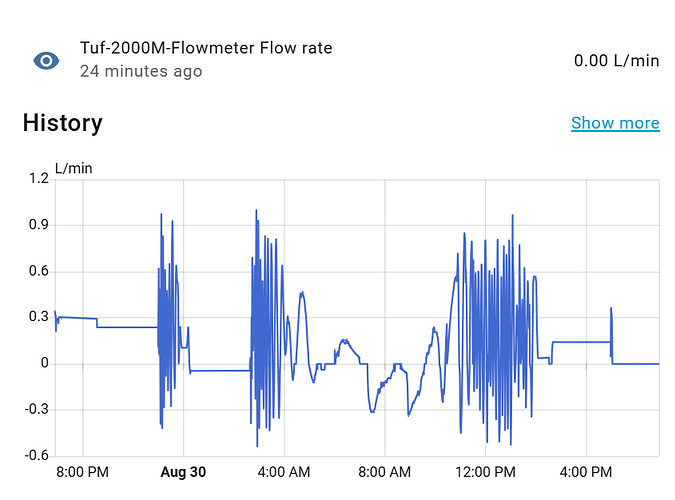

The resulting flow numbers make no sense at all either. Even with all valves closed I’m running about 0.5 gallon/minute. Zeroing things out doesn’t improve the situation. Large or no flow makes no difference either.

Does anyone have this working by chance? Any tips you can share to get this working would be much appreciated!